Take control of your production planning. Intuitive, cost-effective, integrated.

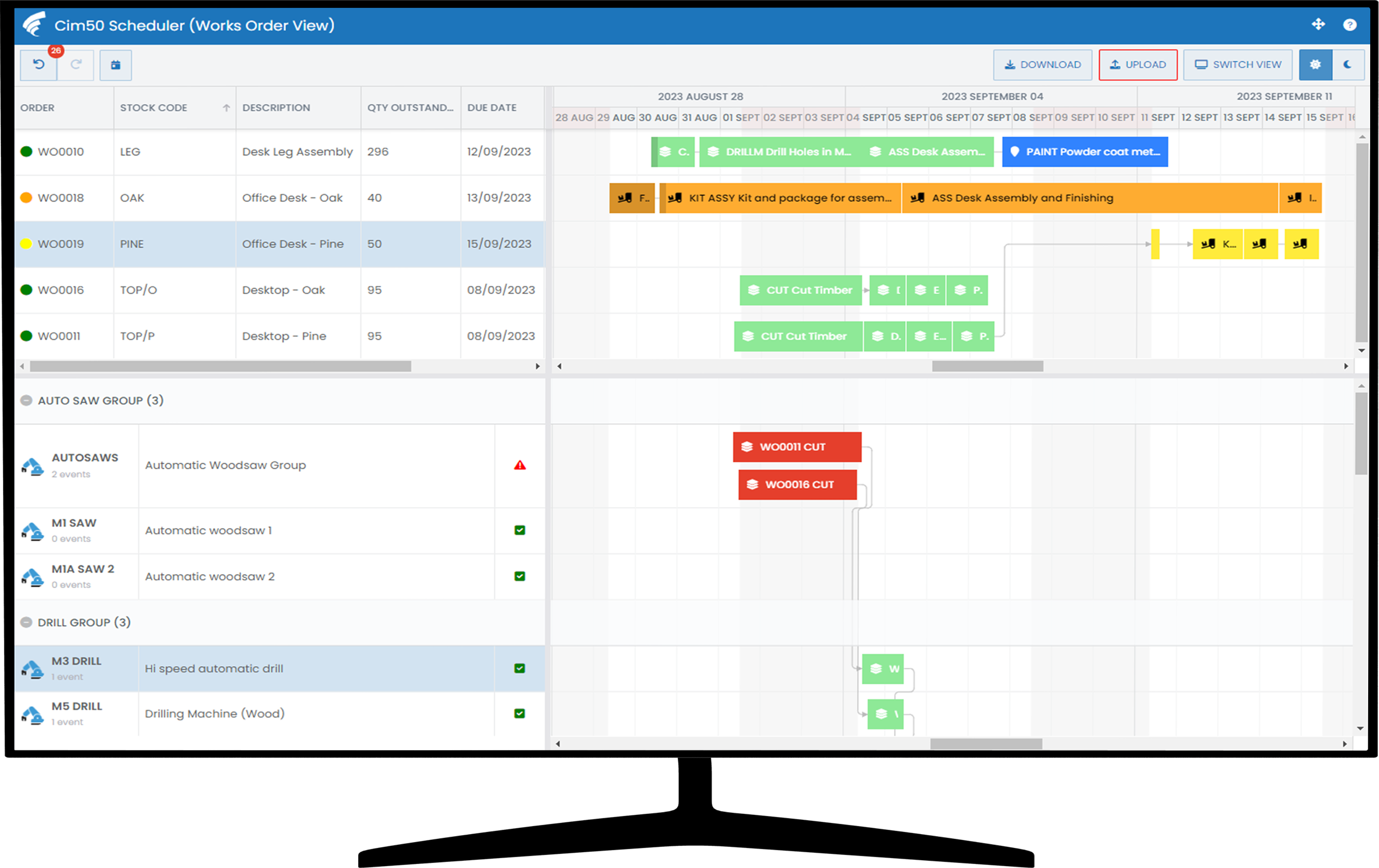

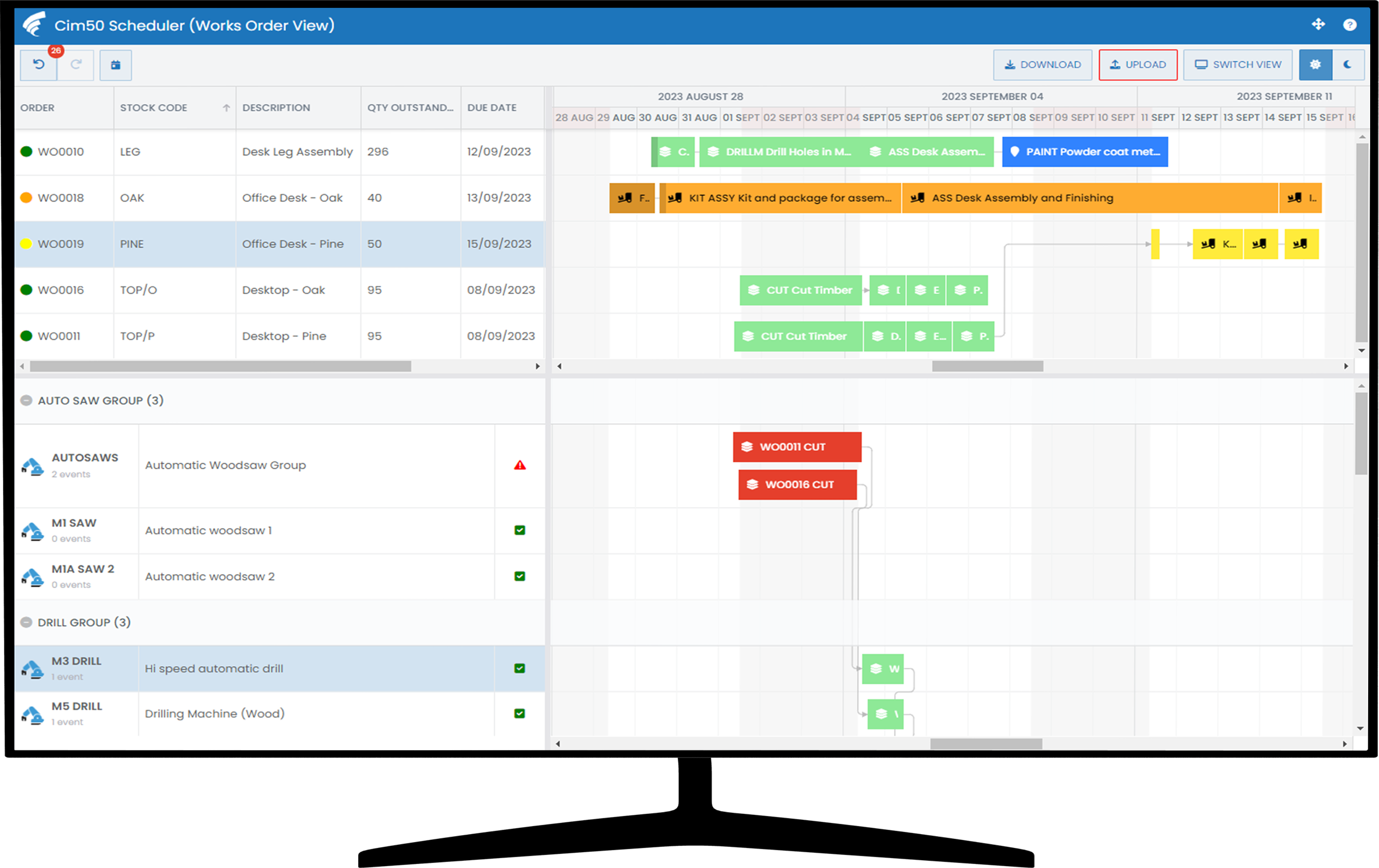

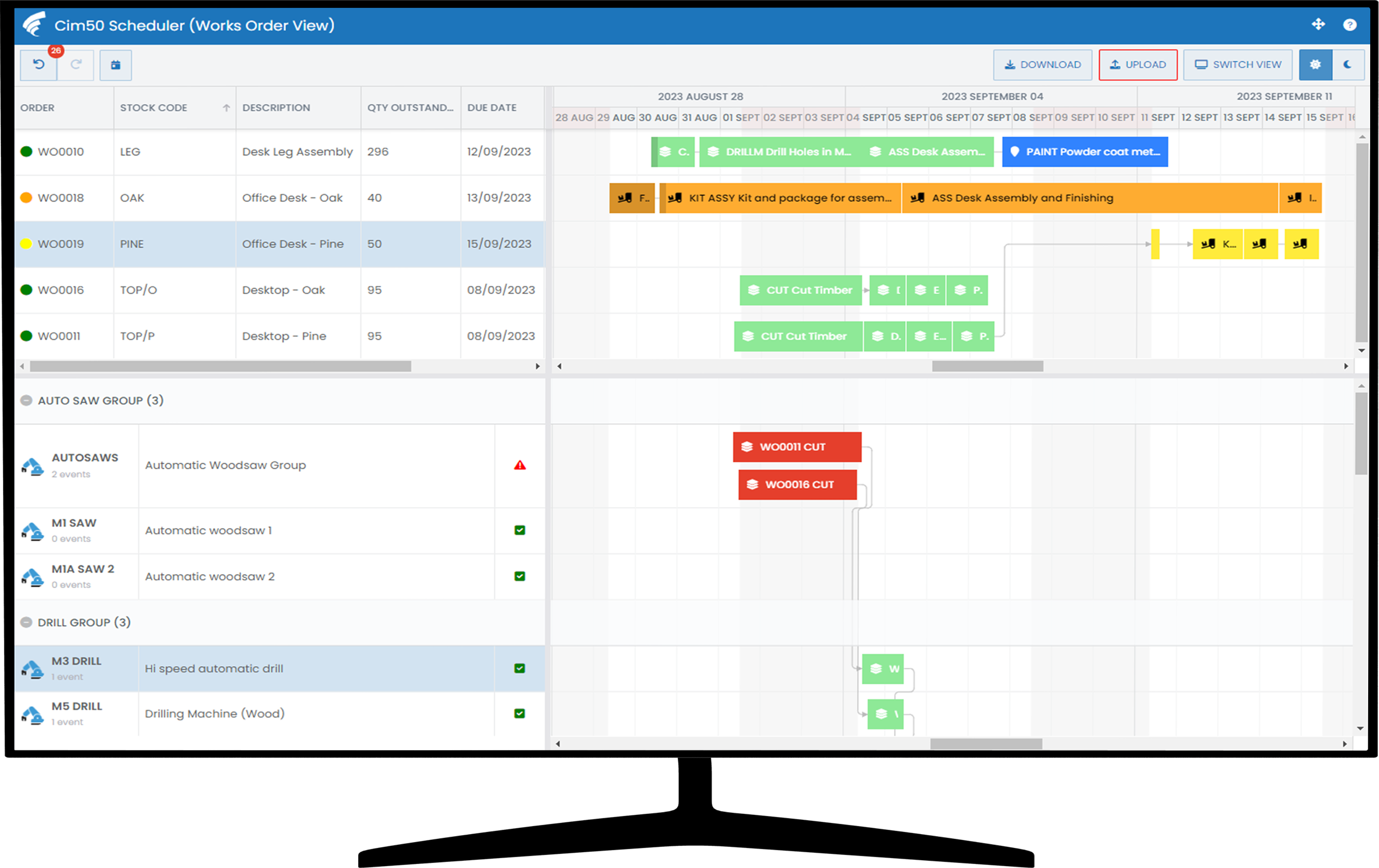

Visualise your production schedule and control your shopfloor workload with our intuitive and easy to use interface. Simply drag and drop…

Group your resources and schedule production based on the capacity and availability of labour resources, machine resources or both.

Quickly see shopfloor workload and take control of your production plan to improve your manufacturing efficiency.

Predict and resolve future resource conflicts and overloads to optimise the production plan to meet customer demands.

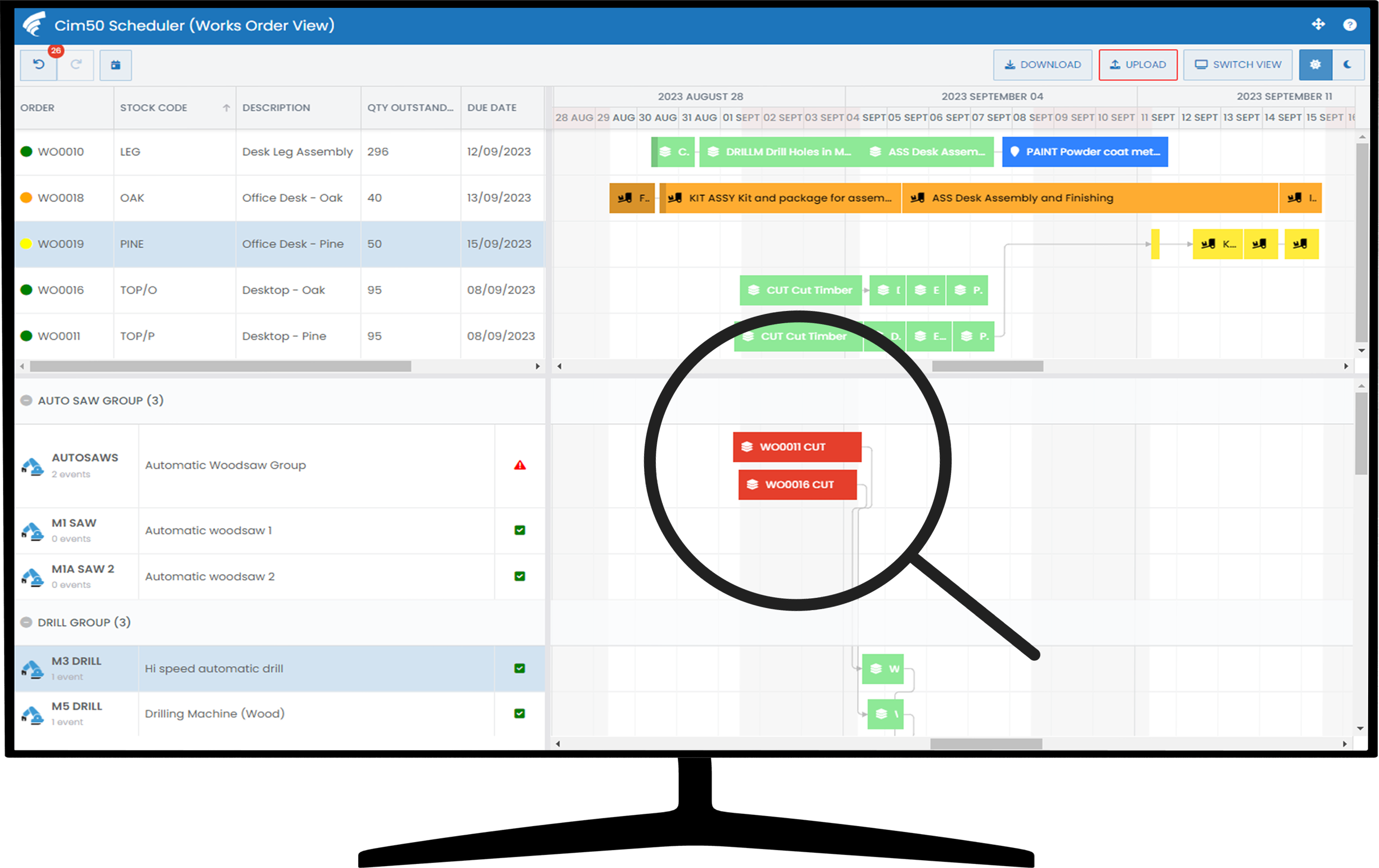

Resolve machine and labour resource conflicts in real-time to ensure manufacturing processes run smoothly and on time across the entire shop floor.

Conflicts are highlighted to the user for review and the intuitive Graphical Scheduler interface provides the ability to drag and drop operations affected to alternative times or resources, whilst providing on the spot feedback as to whether the results of the user interaction will create further resource conflicts or the works order will become overdue or at risk of doing so.

Furthermore if the changes don’t work, there is the option to undo them, therefore providing ‘What if’ functionality for production planners.

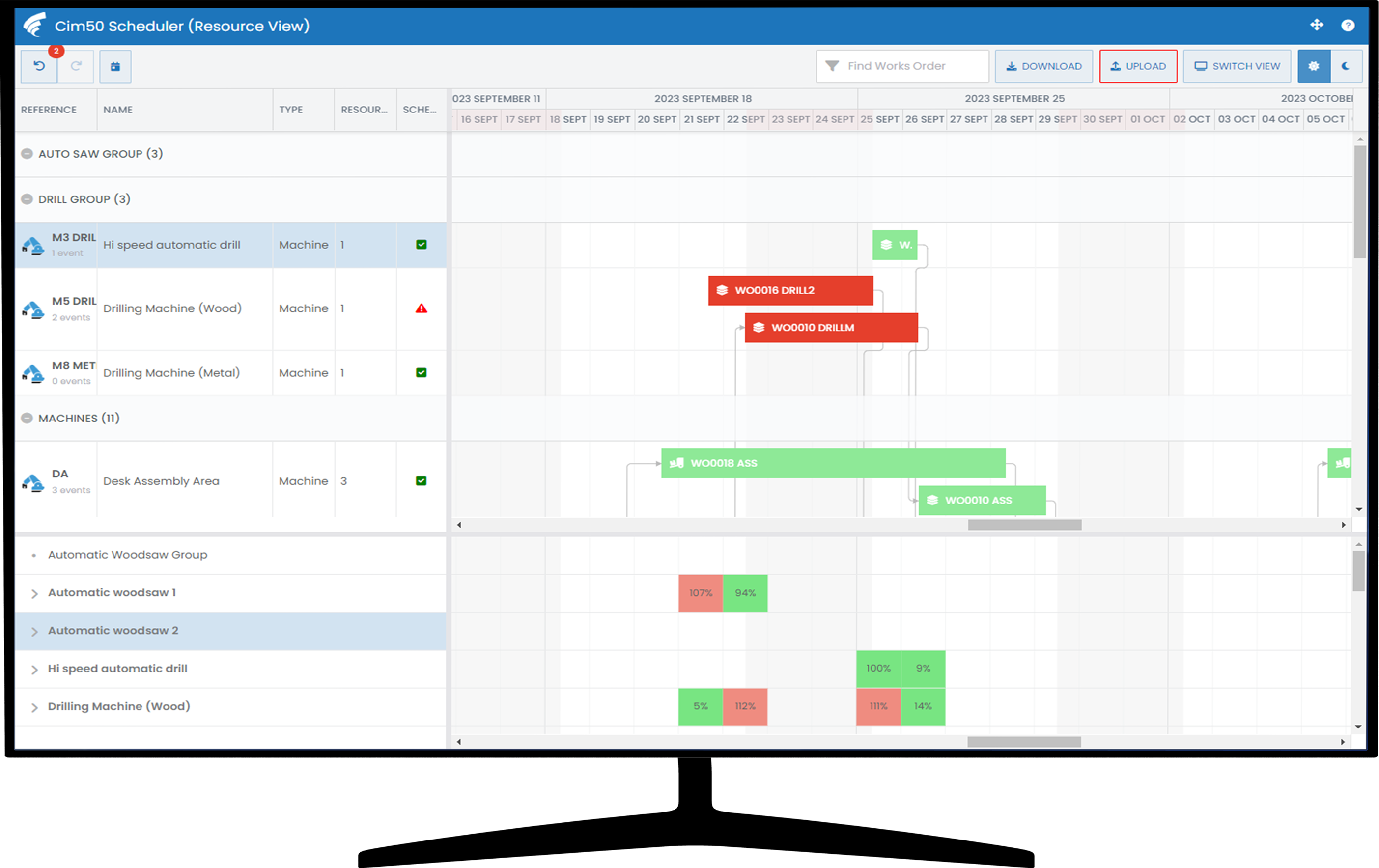

Review colour-coded utilisation of resources by percentage to get an understanding of overloads for labour and machine resources, factory load imbalances and where they occur.

Resolve overloads and imbalances within the graphical scheduler in advance of these impacting production to maintain an efficient factory.

The setup of resources and their availability is carried out from within the CIM manufacturing solutions. This allows the the resource utilisation view to be based on the individual calendars and resource capacity, with options for the grouping of similar resources able to carry out the same tasks, enabling the scheduler to match the hours different resources work and how the production operations are carried out.

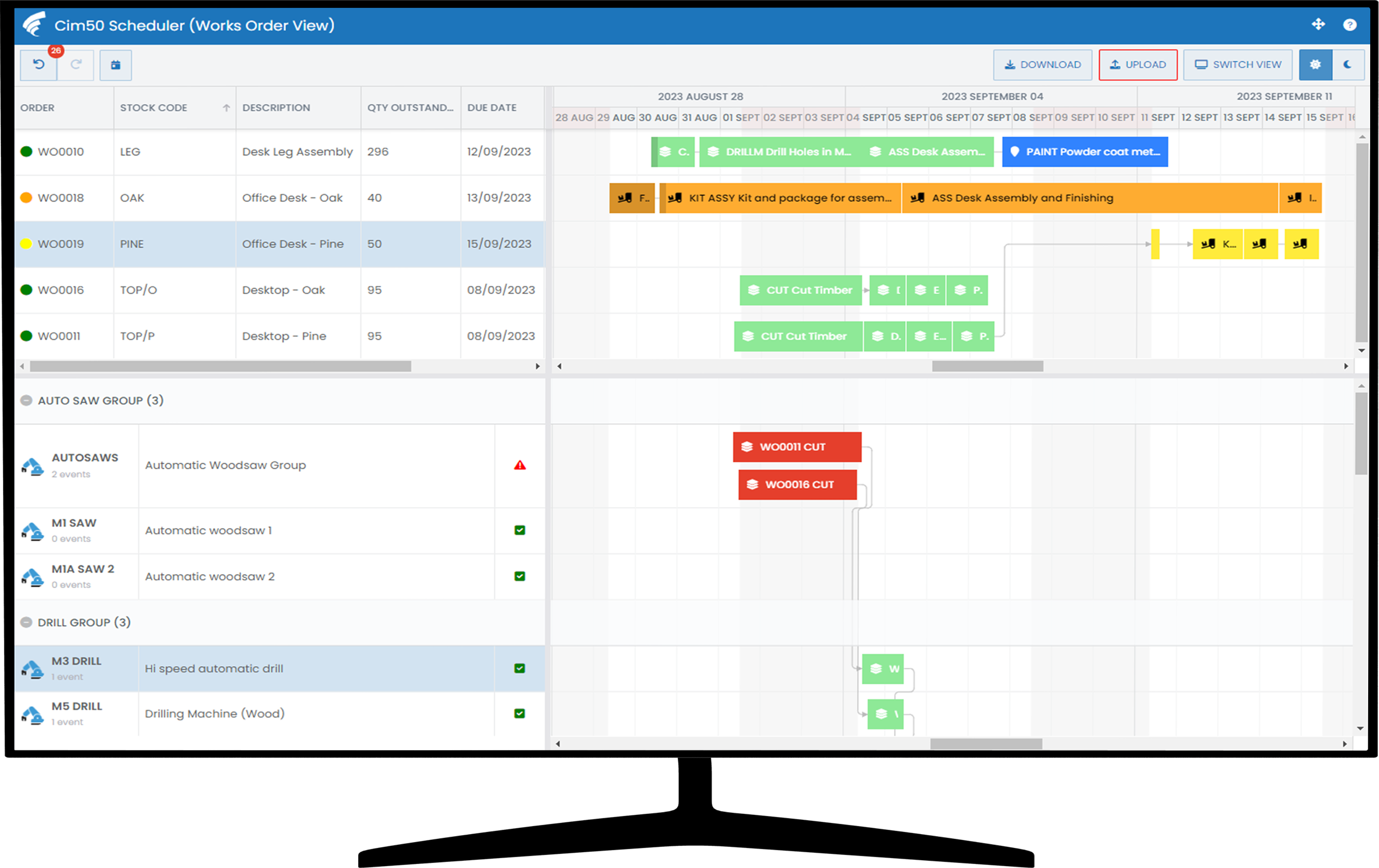

Scheduling individual operations from the routings of the outstanding works orders present in the CIM manufacturing solutions, for enhanced visibility the Works Order Planning view provides production planners with a complete overview of all works orders and their operations across the whole business.

Highlighting late and at risk orders, as well as conflicting operations based on their planned start dates, setup times, runtimes, delays and available capacity, ensures scheduling issues can be dealt with as soon as they are identified.

Within the constraints of resource availability and capacities that have been defined in the CIM Manufacturing resources, using drag and drop functionality there is the ability to resolve issues with works orders and operations to meet planning deadlines, before passing back the changes to the CIM Manufacturing and updating works orders.

To avoid operations being scheduled out of sequence, operation dependency is utilised by the CIM Scheduler. This links operations from the same works order together with arrows directing from one operation to the next.

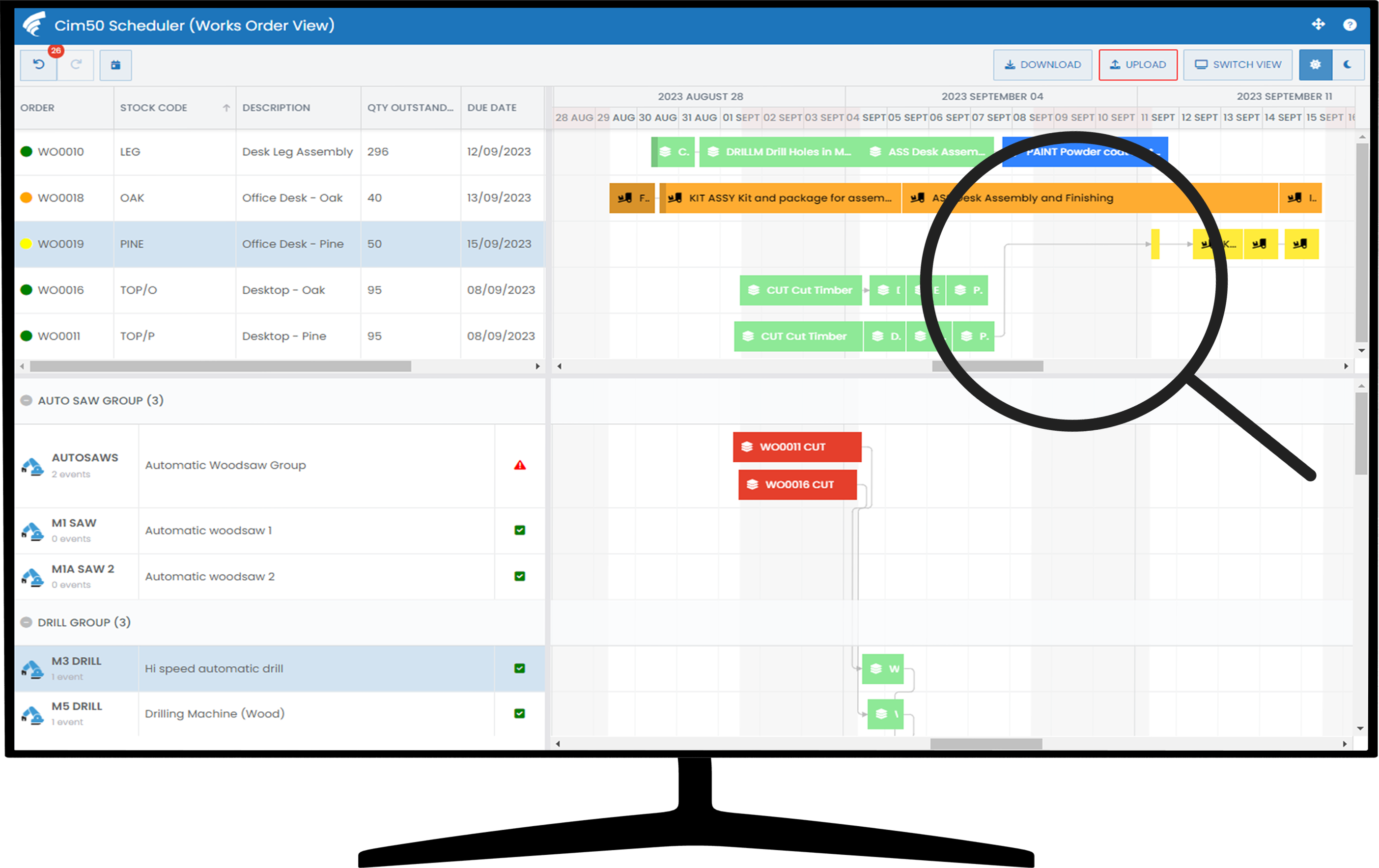

If an operation is moved to a future date, any operations beyond this date will be automatically re-scheduled to later dates with any resource conflicts or affect to works order end dates highlighted immediately, alerting the production planner to take action.

This is also the case for firm-linked sub-assembly and finished goods works orders. If the last operation of the linked sub-assembly is scheduled beyond the start date of the first operation of the finished item, the finished item works order operations will be re-scheduled, thus not allowing a finished item to be started before a sub-assembly has been completed, keeping production aligned.

In a similar manner to the CIM Manufacturing solutions, across the CIM Graphical Scheduler views, colour coding is employed to highlight late works orders, at-risk works orders, resource conflicts and resource overloads, allowing any issues to be identified and addressed from the scheduler in advance of commencement works.

For a fully joined up manufacturing and scheduling solution, the CIM Graphical Scheduler is fully integrated with the Cim50 Manufacturing and Cim200 Manufacturing solutions.

A click of a button allows the reading of all the required data for scheduling from each solution. No data is held within the CIM Graphical Scheduler itself, therefore providing a single source of data for production planners and other CIM software users to work with.

If any changes are carried out to works order operations from within the scheduler, they can be uploaded back to the CIM Manufacturing solution.

Any changes that have been made to works order dates, operations times and operation resources since download to the scheduler will be reflected in the CIM Manufacturing works order module and captured in each works order’s audit log providing full visibility.

Inline with our CIM Manufacturing solutions, during the scoping and development of the Graphical Scheduler, careful consideration of the user interface has taken place, putting ease of use and usability at the forefront of its design.

This has resulted in an intuitive and clean user interface, which has a minimalist look and feel, whilst retaining a feature-rich planning and scheduling solution fit for the modern manufacturing business.

Features | Description |

|---|---|

Locking Works Orders and Operations | Once a production plan has been finialised, firm it up by locking works orders and individual operations to ensure no scheduling changes can be made. |

Review Cim50 and Cim200 Works Order Details | For a complete overview, view works order and operation details within the graphical scheduler user interface, including dates, linked customer orders, run-times, setup times, delays and routing notes. |

Filter, Sort, Group | Hone down onto the data which is relevant to the planning process by filtering, sorting and grouping works orders and resources from within each of the scheduler views. |

Schedule By Labour, Machine or Both | To enable the Graphical Scheduler to plan against the types of resources that are relevant to the business when production planning, choose whether labour resources, machine resources or both are considered when scheduling. |

Resource Grouping | Ensure processes are not carried out by or moved to an incorrect resource type, by grouping labour and machine resources. These are setup from within the CIM manufacturing solution and are taken into account by the graphical scheduler. |

Multiple Planning Calendars | Setup a single company wide calendar or individual calendars for each labour or machine resource to allow the scheduler to plan to the hours the factory and specific resources work. |

Our Graphical Scheduler integrates with our manufacturing solutions Cim50 and Cim200. The scheduler is:

Device Agnostic

Web-Enabled

Locally Hosted

It also has multi-user capability. The Cim200 version also has multi-site functionality.

In Cim50, the Scheduler will be an additional module within the Cim50 Manufacturing range. In Cim200, the Scheduler is included as standard for customers onboarding from v2024 onwards but can also be added to existing Cim200 solutions. If you would like a quote for adding the Scheduler to your current CIM system, please contact us.

Can’t find the answer you’re looking for? Contact Us

A graphical scheduler is a visual representation of a scheduling system that displays processes on a timeline to aid in planning and managing of production activities.

Yes, however we do recommend a workable sized screen.

With the relevant security precautions and IT provision, it is possible to access the scheduler from outside the business.

The scheduler draws its data directly from either the Cim50 or Cim200 manufacturing solutions, allowing the production plan to be reviewed and manipulated, providing ‘What if’ functionality before committing back to the CIM manufacturing solution.

It is possible to see available capacity of resources by percentage within utilisation view, based on the resources and calendars setup within the CIM Manufacturing solution.

Yes, based on the resources setup within the CIM Manufacturing solution, the works order view highlights resource conflicts based on their availability.

Our Graphical Scheduler is part of both our Cim50 and Cim200 solutions. Find out more about them here:

Modular manufacturing software that syncs in real time with Sage 50 Accounts.

Cost-effective option with lower system requirements suitable for smaller businesses. Cim50 is a modular, software meaning businesses can pick and choose modules to suit their needs and budget.

Suitable for businesses with between 1 and 20 concurrent users.

Advanced manufacturing add-on fully integrated within Sage 200 Professional.

Comprehensive and feature-rich solution suitable for medium to large UK manufacturing businesses. Cim200 is not held back by the limitations of Sage 50 Accounts and is run on Microsoft SQL.

Suitable for businesses with up to 100 concurrent users.

If you have any questions or wish to see a demonstration of the Scheduler, please use the form below and we’ll be in touch.

"*" indicates required fields

Park House, Franconia Drive

Nursling Industrial Estate

Southampton

Hampshire

SO16 0YW