Maximum Build

The Max. Build screen provides you with the maximum quantity that could be manufactured for the product selected, based on component and sub-assembly stock availability.

By default, the Max. Build calculations are based on current stock availability of the top level components only. You have the option of carrying out a Max. Build, assuming that you were to manufacture sub-assembly items as well, based on the sub-assembly component availability.

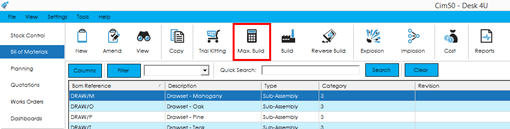

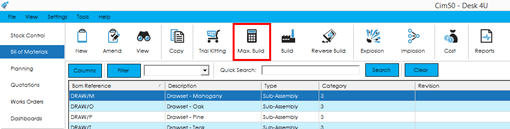

Processing a Max Build

To carry out a max build, select the BOM you would like to perform a max build enquiry on using the ‘Bom Reference’ dropdown. If you had a BOM selected in the BOM list when opening the screen, the Bom Reference will be pre-populated with that BOM, and the calculation automatically performed.

When calculating the max build quantity, the system will go through each component on the BOM and perform a simple division sum.

Max. Build Calculation: Component Free Stock / Component Stock Unit Qty Required = Can Make Quantity

Once the system has calculated the ‘Can Make’ quantity for each component, the component with the lowest figure provides the ‘Max. Build’ quantity.

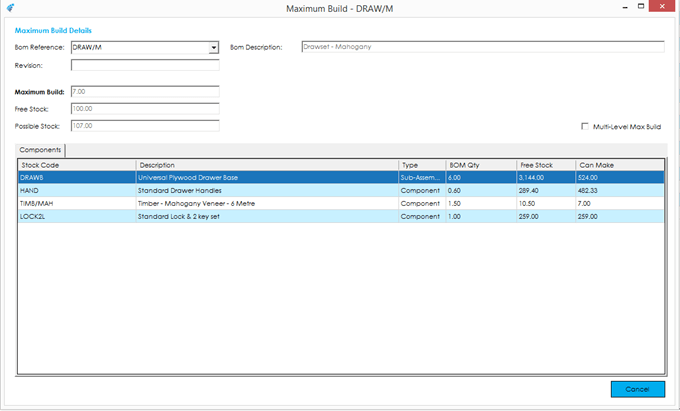

Max Build Screen

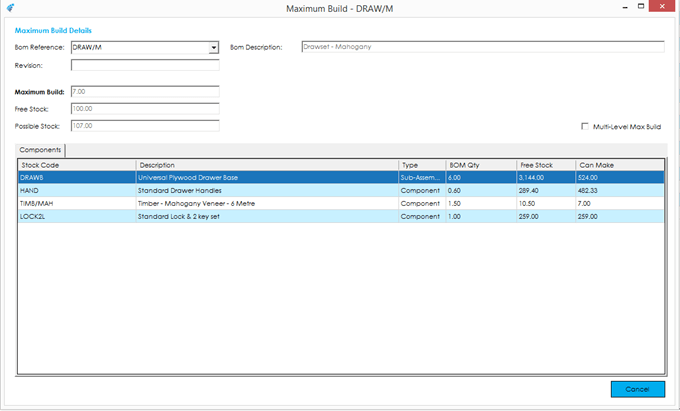

Further information on the fields displayed on the Max. Build screen can be found below:

Bom Reference: The BOM that the Max. Build calculation has been performed for.

Bom Description: The description for the BOM item.

Revision: The revision number for the BOM item (as defined on the BOM record).

Maximum Build: The calculated quantity that could be manufactured based on current component stock availability.

Free Stock: Current free stock quantity for the BOM Item.

Possible Stock: The potential quantity you could have in stock by combining the Free Stock & Max. Build Quantities.

The ‘components grid’ lists out the components included in the Max. Build calculation. The grid contains the following columns:

Stock Code: The component item stock code.

Description: The component item description.

Type: The component item type, as determined from the stock record type on the component stock record.

BOM Qty: The component quantity defined on the BOM record.

Free Stock: The current free stock quantity for the component item.

Can Make: The quantity of the top-level item that could be made, based on the Max. Build calculation defined above.

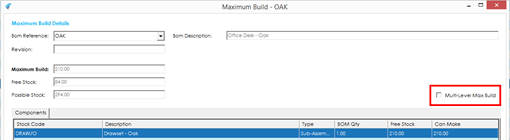

Multi-Level Max Build

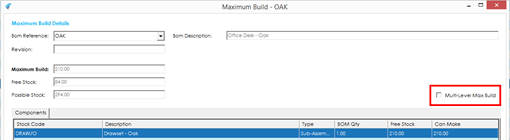

If required, the system can perform a Max. Build calculation based on the assumption you would also manufacture sub-assembly items. This is based on the availability of components that the sub-assemblies require.

To perform a ‘Multi-Level Max. Build’, click on the ‘Multi-Level Max. Build’ check box. The system automatically performs the calculations once selected.

Clicking this option will present a slightly different view in the Components grid.

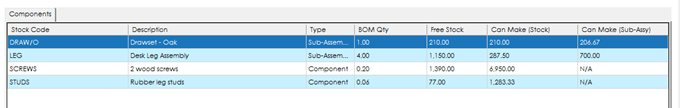

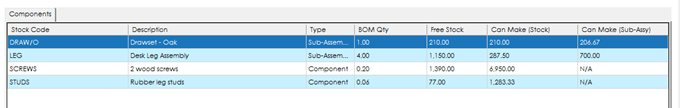

The ‘Can Make’ column is re-labelled to ‘Can Make (Stock)’, and an additional column is included ‘Can Make (Sub-Assy)’.

Can Make (Stock): This column displays the quantity that could be made based on the ‘Free Stock’ availability for the component/sub-assembly item.

Can Make (Sub-Assy): This column displays the quantity that could be made if you were to manufacture the sub-assembly item. This figure is based on the availability of component stock required to manufacture the sub-assembly item. If the item listed in the grid is not a sub-assembly item, this column will display “N/A”.

Once the system has calculated the ‘Can Make (Stock)’ and ‘Can Make (Sub-Assy) quantity for each component/sub-assembly, the component/sub-assembly with the lowest combined figure, provides the ‘Max. Build’ quantity.