The MRP Output log is a useful tool for interrogating any queries that rise regarding MRP Recommendations. It provides a complete detailed run through of the MRP run including what demand was read, what items it processed, and why.

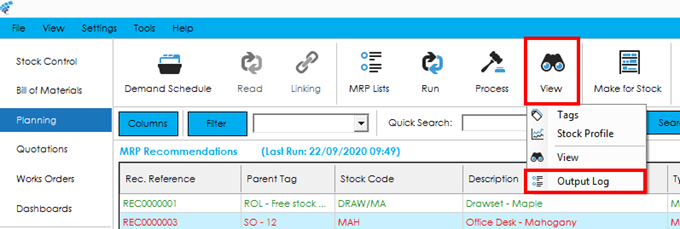

You can access the output logs screen by selecting View > Output Log from the ‘View’ menu, or via the right click menu.

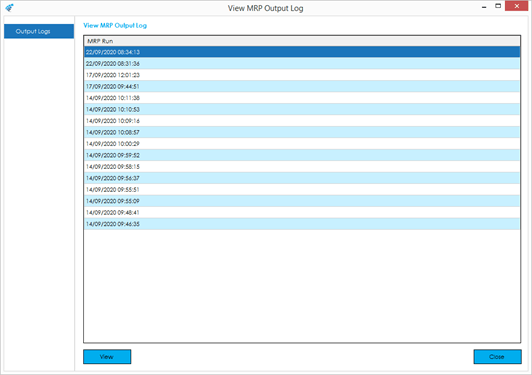

You will be able to select and view the Output Logs from previous MRP runs processed in the previous 10 days.

To open the relevant output log, highlight it in the grid and either double click or press the View button.

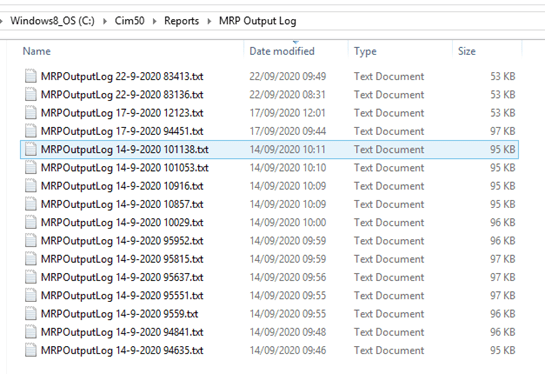

Note: The MRP Output Log files are physically saved in the Cim50 Share directory, in the Reports > MRP Output Log Folder.

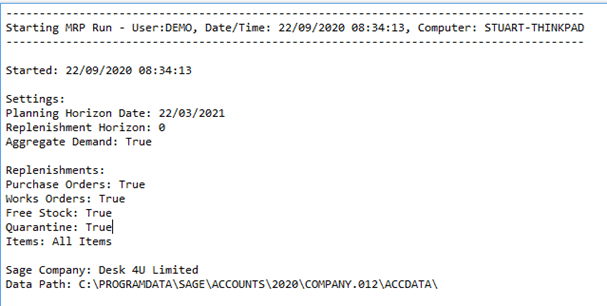

The MRP Output log is a large text file. Reading it from top to bottom it contains the following information:

Firstly, the date and time the MRP run was processed, and which person/computer processed it.

Beneath that is the settings that were selected when the MRP run was processed. These settings were defined in the Running MRP section.

Then the log displays which Sage 50 Accounts company it is interrogating, and the associated data path.

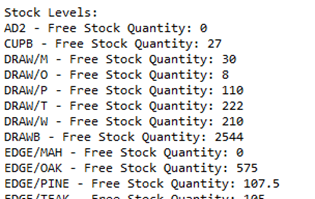

The log then lists the free stock quantities at the time MRP was run. Each stock record included in the MRP run is listed.

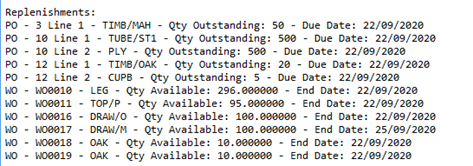

Following the free stock quantities, the log then details the replenishments that have been included in the MRP run, displaying the type of replenishment, reference, stock code, quantity available and expected receipt date.

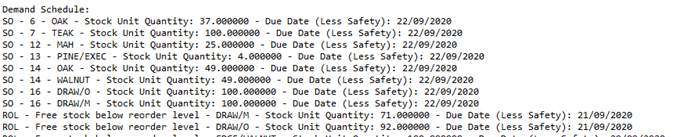

It then details all the demands included in the MRP run, displaying the demand type, reference, stock code, demand quantity and safety due date.

The log then displays an output for each item processed.

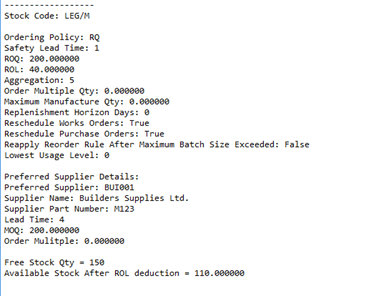

Information displayed depends on the item type (Manufactured or Purchase). Information includes:

- Ordering rules defined on the Stock Record MRP tab.

- The preferred supplier details (purchase items only)

- Free Stock Quantity

- Free Stock after ROL deduction (items with ROL only)

It will then show the demands that were processed, and what actions it took when processing those demands:

The above will show when no demand was present for the item.

The above shows a reorder level demand, the quantity required for that demand, the due date and order rule it was processed using.

It shows the available stock at the point of processing that demand (0), then the action taken. In the above example an MRP recommendation was raised to cover the demand.

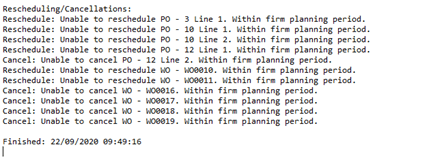

Lastly it shows the rescheduling and cancellation recommendations.