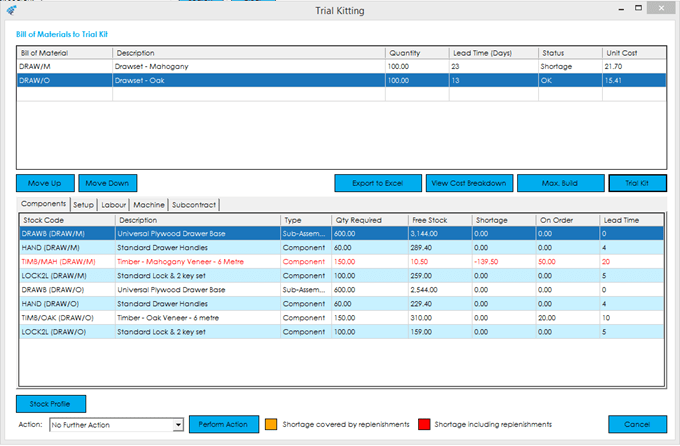

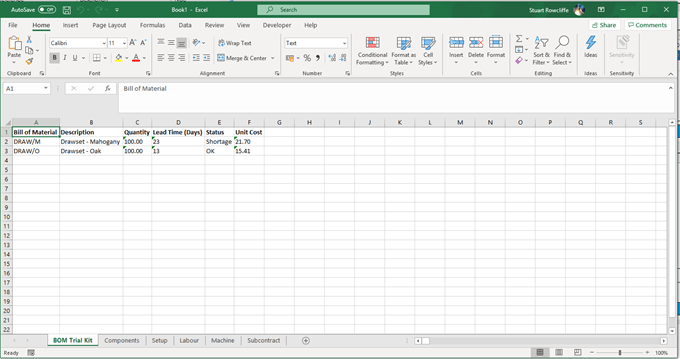

Once you have performed the trial kit, you will be presented with a list of components that were trial kitted. The Lead Time, Status, and Unit Cost columns will be populated, and you will see some additional buttons displayed.

Knowledgebase

Home > Knowledgebase > Cim50 > Bill of Materials > Trial Kitting > Analysing Results of a Trial Kit

Once you have performed the trial kit, you will be presented with a list of components that were trial kitted. The Lead Time, Status, and Unit Cost columns will be populated, and you will see some additional buttons displayed.

The components grid details the component items that were processed during the trial kit. The grid contains the following information:

Stock Code: The component item stock code, along with the parent BOM the item belongs to (contained in brackets).

Description: The component item description.

Type: The component item type, as determined from the stock record type on the component stock record.

Qty Required: The component quantity required based on the BOM trial kit quantity.

Free Stock: The available stock for the component item at the point that item was processed.

Note: In the above screenshot you can see a common component ‘LOCK2L’ shows 259 available initially, but then 159 when the 2nd BOM that contains that item is processed. The system having deducted 100 from the 1st line requirement.

Shortage: The shortage quantity calculated based on the component quantity required and the available stock.

Note: If an item has a shortage, it will be highlighted in either orange or red. Items highlighted in orange indicate there is a shortage, but that shortage could be covered by replenishments due in (works order completions or purchase order receipts). Items highlighted in red indicate there is a shortage, and there are not enough replenishments due in to cover the shortage.

On Order: The quantity that is currently outstanding on purchase orders or works orders.

Lead Time: The component lead time as defined on the preferred supplier on the component stock record. This will show ‘0’ for an item marked as a sub-assembly or finished good.

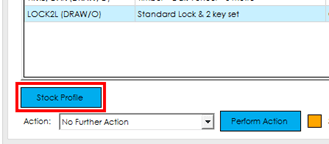

Pressing the Stock Profile button will open the stock profile screen for the highlighted component item.

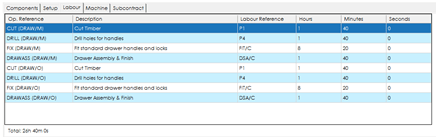

There are 4 tabs dedicated to the resource requirements for the items that have been trial kitted.

Setup/Labour/Machine: These tabs display the operations required to produce the items trial kitted, along with the times required for each operation to manufacture the quantity that was trial kitted.

The relevant grids contain the following information:

Reference: The operation reference, along with the parent BOM the operation belongs to (contained in brackets).

Description: The operation description.

Labour/Machine Reference: The Labour & Machine tabs contain a column detailing the labour or machine reference defined on the operation.

Hours/Minutes/Seconds: The Setup/Labour/Machine hours, minutes and seconds calculated based on the quantity being trial kitted, the quantity per run (Labour & Machine only), and the time defined on the operation setup/labour/machine resource.

A total time requirement is displayed underneath each relevant grid, detailing the total setup/machine/labour time required to process all the items that were trial kitted.

Subcontract: The subcontract grid details any subcontract operations that would be required to be processed to manufacture the items being trial kitted. The grid contains the following information:

Reference: The operation reference, along with the parent BOM the operation belongs to (contained in brackets).

Description: The operation description.

Hours Off Site: The number of hours the subcontract supplier requires the items to process the operation. This is calculated from the quantity being trial kitted, and the sub-contract operation quantity breaks defined on the operation.

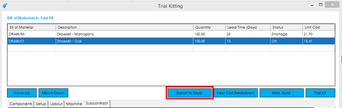

When a trial kit is processed several additional buttons are displayed.

Export to Excel: The Export to Excel button exports the trial kit information out to excel. Within the exported document you will find a worksheet created for the BOM items that were trial kitted, along with a worksheet for Components, Setup, Labour, Machine, and Subcontract.

The excel document will open automatically once the export has completed.

View Cost Breakdown: If the setting ‘Cost BOM when trial kitting’ is enabled, you will see a button enabling you to view a detailed cost breakdown of the unit cost calculated from the trial kit. Please visit this section for more information on this screen.

Max Build: If an item has a shortage, you can see the maximum you could manufacture, based on the component stock availability. This button provides a shortcut to the ‘Maximum Build’ screen. Please visit this section for more information on this functionality.

Park House, Franconia Drive

Nursling Industrial Estate

Southampton

Hampshire

SO16 0YW