Reversing a Current BOM

There may be scenarios where a company buys a kit of items and wishes to stock the items within the kit individually. The reverse current BOM enables you to reverse the finished BOM item from stock and book the component items within the BOM into stock.

Processing a Current BOM Reversal

To reverse a current BOM, select the Current Bill of Material option at the top of the screen:

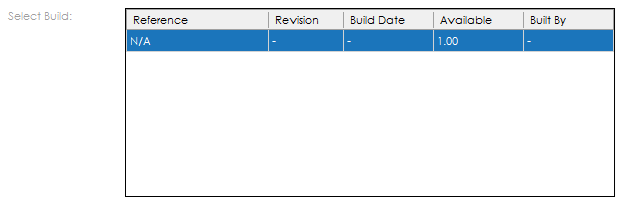

You must then select or type a BOM you wish to reverse build using the ‘Bill of Material’ dropdown. Upon selecting or typing in a BOM reference, you will be presented with a single row in the ‘Select Build’ grid.

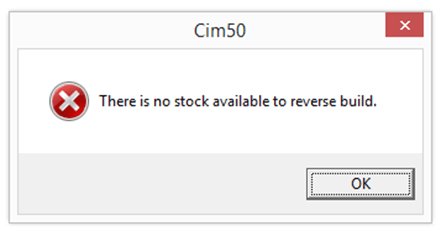

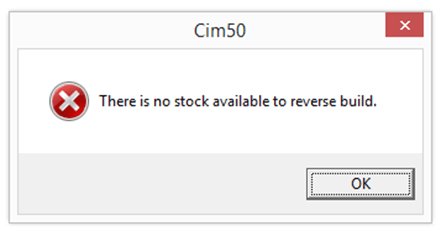

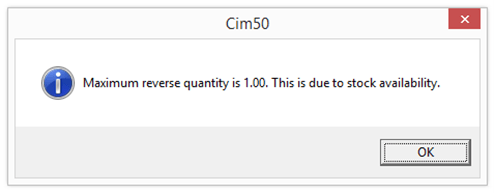

If there is no stock available for the select BOM item, you will be presented with the following message:

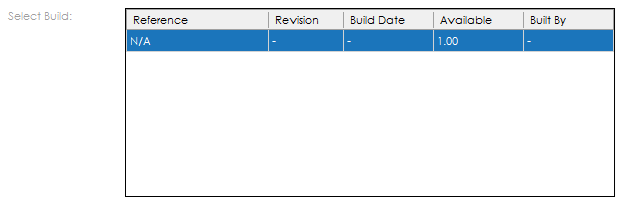

Assuming there is stock available to reverse, you will see one line populated in the central grid.

This grid contains the following information:

Reference: Displays “N/A” as we are not reversing a specific BOM.

Revision: Displays “- “, as we are not reversing a specific BOM.

Build Date: Displays “- “, as we are not reversing a specific BOM.

Available: The quantity available to reverse build. The free stock quantity available.

Built By: Displays “- “, as we are not reversing a specific BOM.

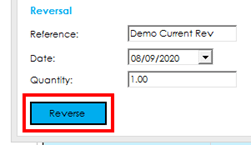

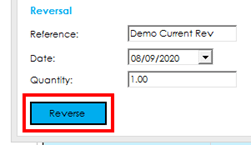

Within the ‘Reversal’ section of the screen you can define a reference, which will be displayed in the Stock Transaction History, along with confirming the date that you would like the reversal to use, and the quantity to reverse from the build.

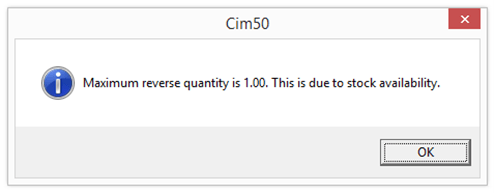

Note: If you enter a quantity greater than is available, you will be presented with the following message:

The quantity will then revert to the quantity available.

To process the reversal, click the Reverse button.

A confirmation message is displayed, where you can confirm if you wish to continue with the reversal or not.

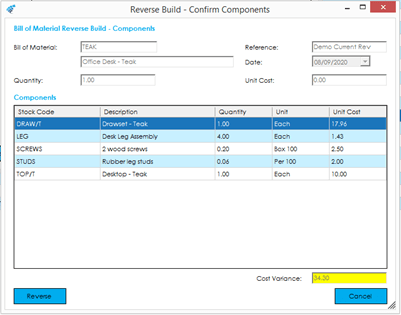

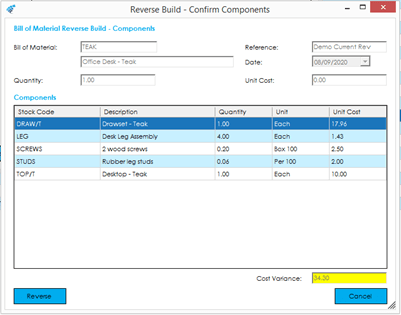

Once confirmation has been made, you are presented with a screen where you can confirm the components that should be reversed into stock. This list is pulled from the current components listed on the BOM record.

This screen contains the following information:

Bill of Material: The BOM record that is being reverse built, with the description showing beneath.

Quantity: The quantity of the finished item that is being reverse built.

Reference: The reference entered in the reversal details section of the previous screen.

Date: The date the reversal will use.

Unit Cost: The current unit cost for the finished item. This is based on the ‘Last Cost Price’ for the finished item.

The components grid lists out the components defined on the BOM Record and contains the following information.

Stock Code: The component item stock code.

Description: The component item description.

Quantity: The quantity that will be reversed into stock. This figure is calculated based on the finished item reversal quantity and the quantity defined on the BOM record.

Unit: The unit of measure defined on the component item in the BOM Record.

Unit Cost: The current unit cost for the component item. This is based on the ‘Last Cost Price’ defined on the stock record.

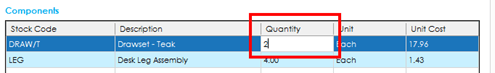

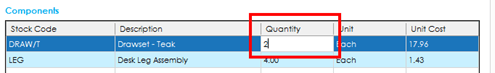

You can adjust the quantity of each item that should be reversed into stock. This gives you flexibility to control what is reversed into stock and may be used if one of the component items was unable to be returned as part of the reversal process.

To adjust the quantity, click into the relevant line in the component grid and select the quantity cell. You can then overtype the quantity as required.

You can also adjust the unit cost price for individual component items as required by the same methodology.

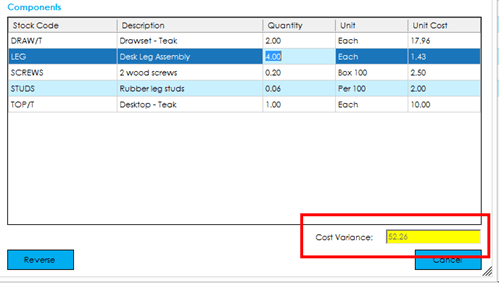

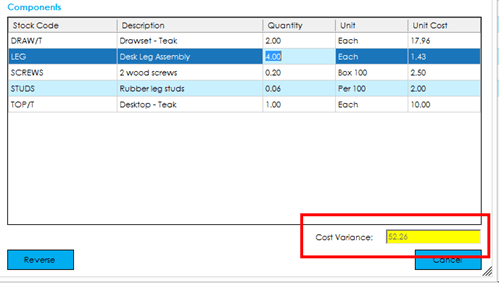

Cost Variance

When processing a BOM build, it is likely that a cost variance will be encountered. This is the difference between the finished item unit cost, and the sum of the component unit costs, based on the quantities being reversed.

The variance cost is displayed in the bottom right corner of the screen and is highlighted in yellow, if a variance is present.

If the variance figure is positive, the value of the component items that will be booked into stock is greater than the value of the finished item that will be booked out of stock. If the variance is negative, the finished item value that is being booked out of stock is greater than the component values that will be booked into stock.

This will impact the overall stock valuation and should be considered and explained.

Cost variances can be managed by adjusting the component item unit costs, as required, to bring the variance to ‘0’. The net effect of the reverse build would then be ‘0’ on the company’s stock valuation.

Processing a Current BOM Reversal Cont.

Once you have adjusted the component quantities and unit cost prices as required, press the Reverse button to continue the reversal.

Finished Item Traceability

If the finished item that is being reversed is traceable, a ‘Traceable Reverse Build’ screen is displayed, where you can confirm the batch/serial number(s) that you wish to reverse. You will be presented with all batches/serial numbers currently in stock.

Functionality on this screen is the same as the traceable adjustment screens covered during Stock Control.

Enter the quantity you would like to reverse against each batch/serial number in the ‘Reverse’ column and press Confirm to continue.

Component Item Traceability

If any of the components defined on the BOM are traceable, a ‘Component Traceability – Reverse’ screen is displayed where you can define the batch/serial number(s) that you wish to create as part of the reversal.

Note: Unlike the Specific Build reversal, the reversal of a current BOM effectively creates new batches/serial numbers in stock that have not previously existed. As such, you must define the batches/serial numbers that will be created at this point.

Functionality on this screen is the same as the traceable receipt/adjustment’s screens covered during Stock Control.

Add Batches/Serial Numbers as required, and press Confirm to continue.

Once the reversal has completed, the screen closes. You will then find the finished item has been adjusted out of stock, and component items adjusted back into stock, with cost prices the same as those defined during the reversal process.

See also

Related

Other tasks