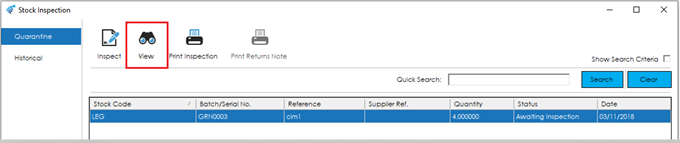

View Quarantine Record

To familiarise ourselves with the Quarantine Records, the ‘View’ Feature will be explored.

Clicking the ‘View’ feature, whilst a record is highlighted, will show the following ‘Inspection Details’ screen:

The screen is broken down into the following sections and the fields and buttons within them are described below:

Quarantine Details

The top section of the screen shows information relating to the items in quarantine, where they came from, who quarantined them and why.

Reference: This is the reference that is entered by you when booking the goods to Quarantine.

Stock Code: The Stock Item that the Quarantine record relates to.

Reason for Quarantine: This is the reason the Stock Item has been transferred to Quarantine, for example from a Bill of Material Build, Purchase Order Receipt, Transfer or Works Order Completion.

Supplier Reference: The Purchase Order number of the goods that were transferred to Quarantine during the Purchase Order Receipt process.

Quarantined By: The Person that quarantined the goods.

Supplier Name: This is the Supplier of the Purchase Order if the goods were transferred to Quarantine during the Purchase Order Receipt process.

Quantity: The quantity of the goods that were transferred to Quarantine.

Quarantine Date: The date the goods were transferred to Quarantine.

Inspection Details

This section of the screen shows information relating to inspection of the goods in quarantine, such as quantities that have passed, or were rejected, Inspection notes and reasons for rejection.

Quantity Passed: This is the Quantity that have passed during the inspection process.

Inspection Date: The date the goods were inspected.

Inspection Number: An inspection number entered or auto generated during the inspection process.

Location: The Location of the goods, generally ‘Quarantine’.

Issue Status: This a field that allows an Issue Status to be entered during the inspection process.

Certificate Number: During the inspection process there is the option to enter a Certificate Number.

Inspection Notes: These are notes that are entered during the inspection process to detail the condition of the goods being inspected.

Were any Rejected? Yes and No radio buttons to denote if any goods were rejected during the inspection process.

Quantity Rejected: This is the Quantity that were rejected during the inspection process.

Reject Number: A Reject Number entered or auto generated during the inspection process when goods are rejected.

Reject Notes: These are notes that are entered during the inspection process to detail the condition of the goods rejected.

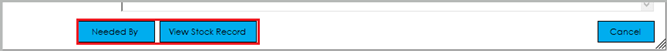

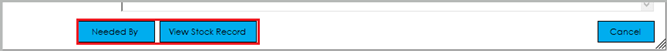

Needed By and View Stock Record

At the foot of the screen are the highlighted buttons, Needed By and View Stock Record.

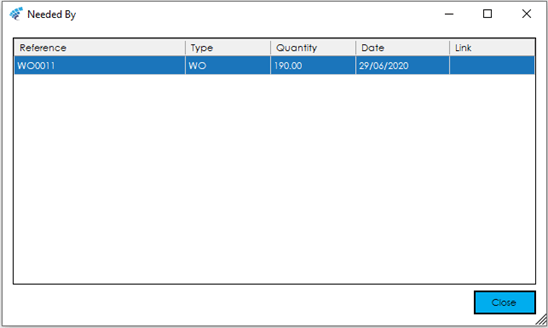

Needed By

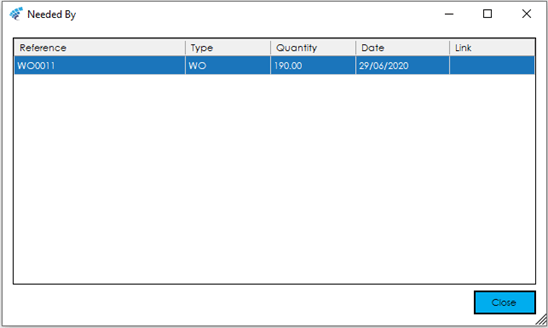

The Needed By button allows the user to identify if the Stock Item being inspected is required for a Works Order component or Sage 50 Accounts Sales Order line and shows if it has been linked by the Planning Module.

The fields within the grid displayed, are described below:

Reference: The Cim50 Works Order Number or the Sage 50 Accounts Sales Order Number requiring the Stock Item being received.

Type: The type of order, WO for Works Order and SO for Sales Order.

Quantity: The quantity required by the Cim50 Works Order Number or the Sage 50 Accounts Sales Order.

Date: The date the component is required by the Cim50 Works Order (Normally the Start Date of the Works Order) or the Due Date of the Sage 50 Accounts Sales Order line.

Link: This denotes if the MRP feature of the Cim50 Planning Module has linked the Stock Item/Purchase Order Line being received to the Cim50 Works Order or Sage 50 Accounts Sales Order. (This will be covered in more detail within Planning and MRP)

Use the Close button to close out of this screen and return to the Inspection screen.

View Stock Record

The View Stock Record button will open the record of the Stock Item concerned for enquiry only. Please see Cim50 Stock Record section of this guide for further details.

See also

Related

Other tasks