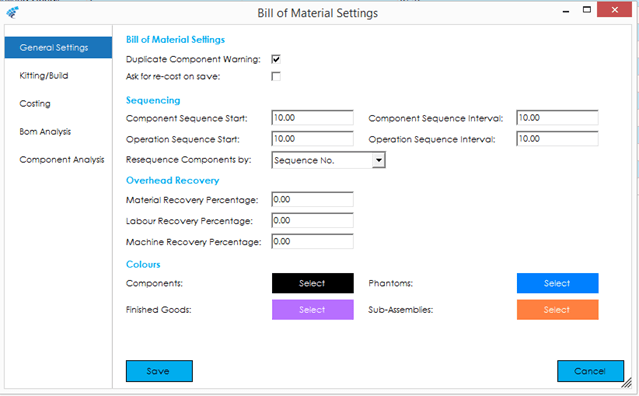

General Settings

The General Settings allow you to configure ‘Defaults’ for various aspects of a New Bill of Material record including processing settings, for adding components and saving records, along with colour codes, that are used to identify different types of items within the BOM module.

The screen is broken down into the following sections, and the fields within them are described below:

Bill of Material Settings

Duplicate Component Warning: This setting determines whether you will be warned when adding a duplicate component to a bill of material or not.

Ask for re-cost on Save: This setting determines whether you will be asked if you would like to re-cost the bill of material when saving.

Sequencing

Both components and operations are referenced within BOMs and Works Orders by ‘Sequence Number’. This section of the settings determines the sequence number intervals that will be used when adding components or operations to a Bill of Material.

Note: When setting your sequence intervals, consider that you may need to add items into the components/operations list at any point in the future. Setting the interval to 1 does not leave space for new items to be placed between existing component/operations without needing to re-sequence them.

Component Sequence Start / Interval: The component sequence start number, and interval by which the sequence will increase with each added component.

Operation Sequence Start / Interval: The operation sequence start number, and interval by which the sequence will increase with each added operation.

Resequence Components by: This option allows you to choose what basis components should be re-sequenced, choosing between Stock Code, or Sequence Number.

Selecting the ‘Stock Code’ option would result in components being sequenced in alphabetical order when you choose to re-sequence them.

Selecting the ‘Sequence Number’ option would result in components being sequenced in sequence number order when you choose to re-sequence them.

A full explanation of these fields and how they are used will be covered in the Cim50 Bill of Materials section of the knowledgebase.

Overhead Recovery Settings

When costing a BOM, overhead costs can be included in the calculated unit cost. Overheads costs are applied on a percentage of either the Material Cost, Labour Cost, or Machine Cost, or any combination of the three.

Material Recovery Percentage: The default percentage that will be applied when creating a new bill of material.

Labour Recovery Percentage: The default percentage that will be applied when creating a new bill of material.

Machine Recovery Percentage: The default percentage that will be applied when creating a new bill of material.

Colour Settings

There are various different BOM Item Types that are used in Cim50. Each item type can be colour coded to make identification easier.

These colour codes are used throughout the BOM and Works Order modules, in both screen enquiries, and some Excel exports.

To amend a colour, click the button for the relevant product type, and choose your desired colour from the colour palette.

See also

Related

Other tasks