The routing list contains all the operations required to manufacture this works order. Typically, a routing list is created with operations added in the order they will be processed during the build and defaulted from the operations of the Bill of Material

There are two types of operations available on a works order, a ‘Standard’ operation, which is processed ‘in house’, or a ‘Subcontract’ operation, which is processed by a subcontract supplier.

To add an operation to the operations list, click in the ‘Reference’ column on the first empty line in the list, and either type, or select your operation from the drop-down list.

Depending on the type of operation you have selected, will determine the details screen displayed beneath the operations grid.

You can Add, Amend, and Delete operations, as necessary.

If you add an Operation, you can then re-sequence if required, in the same way as components. This ensures that the operation is listed and printed on the documentation in the correct order.

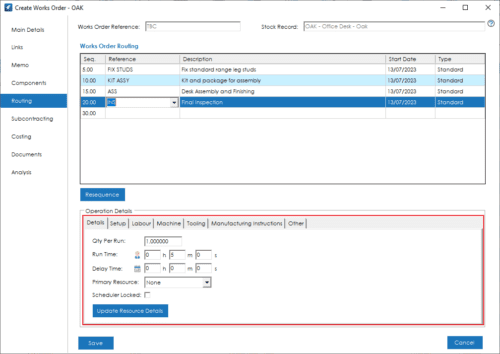

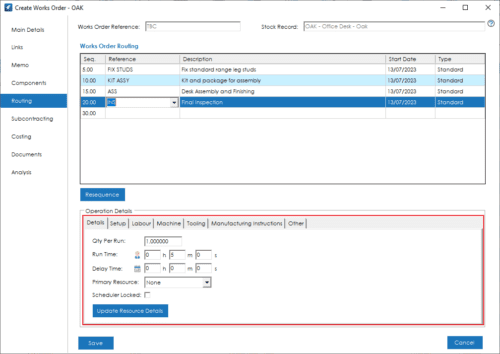

Standard Operations

Details

Qty Per Run: This field determines the number of items that you can process in a single run. This is used in conjunction with Run Time, Labour, and Machine Resources, to calculate lead times, and for costing purposes.

Run Time: This field determines the amount of time required to process a run, based on the quantity per run above.

Delay Time: This field determines whether there needs to be a delay before proceeding onto the next operation. For example, if the operation we were creating was a painting operation, that required the paint to dry before proceeding to the next operation, a delay time would be used to allow for drying time.

Scheduler Locked: This field determines whether this operation is locked from a scheduling perspective. With this field ticked, the operation will not be able to be rescheduled from within the Cim50 Scheduler.

Note: If the ‘Scheduler Locked’ setting on the main details tab is selected, this option within the Routing tab will be ticked automatically and disabled.

Primary Resource: This is the Primary Resource Calendar that you would like the Works Order to utilise when planning manufactured items.

For example you may have a Machine that is available 24/7, or a Labour Resource that works part time, you can therefore instruct the system which resource to plan against.

Setup

If there is any setup associated with this operation, you can specify the time and cost, along with any instructions on this tab.

Setup Time: Determines the amount of time required to setup this operation.

Setup Rate: This is the hourly cost rate associated with the setup of this operation.

Setup Notes: Use this field for any notes that you want the operator to read when setting up the operation.

Labour

If there is any labour resource requirement with this operation, you can specify the labour resource, time, and cost, along with any instructions on this tab.

Labour Reference: Specifies the labour resource used by this operation. The labour resource must exist in the labour resources list. If you enter a labour resource that does not exist, the system will ask you to create it before proceeding.

Note: Default times and costs are pulled through from the Labour resource.

Time: Determines the amount of time required on this operation.

Rate: This is the hourly cost rate associated with the labour resource of this operation.

People: This field identifies the number of people required for this operation. It is used when calculating costs for the operation.

Instructions: Use this field for any instructions you want the operator to read when processing the operation.

Machine

If there is any machine resource requirement with this operation, you can specify the machine resource, time, and cost, along with any instructions on this tab.

Machine Reference: Specifies the machine resource used by this operation. The machine resource must exist in the machine resources list. If you enter a machine resource that does not exist, the system will ask you to create it before proceeding.

Note: Default times and costs are pulled through from the Machine resource.

Time: Determines the amount of time required on this operation.

Rate: This is the hourly cost rate associated with the machine resource of this operation.

Instructions: Use this field for any instructions you want the operator to read when processing the operation.

Tooling

If there is any tooling resource requirement with this operation, you can specify the tooling resource, quantity, and cost, along with any instructions on this tab.

Tooling Reference: Specifies the Tooling resource used by this operation. The tooling resource must exist in the tooling resources list. If you enter a tooling resource that does not exist, the system will ask you to create it before proceeding.

Note: Default quantity and costs are pulled through from the Tooling resource.

Quantity: Determines the number of times this tooling resource can be used on this operation, before requiring replacement.

Unit Cost: This is the unit cost associated with the tooling resource of this operation.

Instructions: Use this field for any instructions you want the operator to read when processing the operation.

Manufacturing Instructions

Use this field for detailing Manufacturing Instructions specific to the operation.

This detail is displayed on shop floor paperwork, such as the Route Card.

Other

Print on Docs: Determines whether this operation will print out on Bom/Works Order documentation.

Overlap: Determines whether the next operation can overlap this one, and by how much (expressed as a percentage).

Piece Work: This field determines whether the operation is costed on a piece work basis or not.

Piece Work Rate: If the operation is costed on a piece work basis, this field determines the rate per quantity specified below.

Piece Work Quantity: If the operation is costed on a piece work basis, this field determines the quantity per rate specified above.

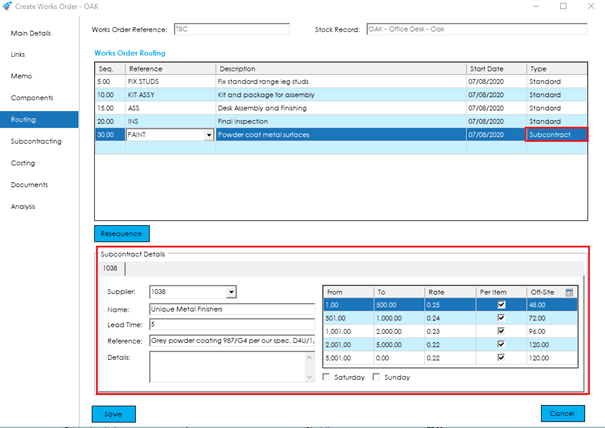

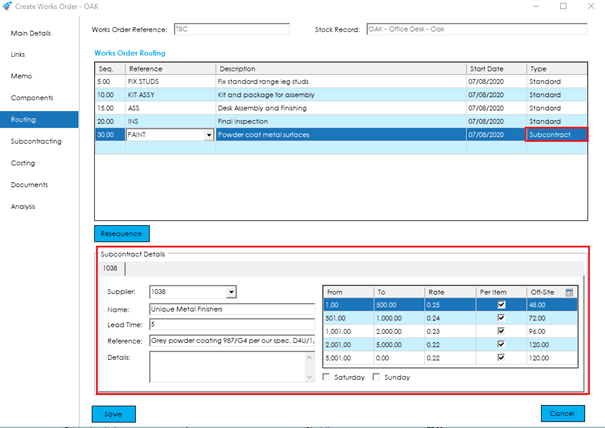

Subcontract Operations

You can specify up to 5 subcontract suppliers on an operation, with one being identified as the preferred supplier.

Supplier: Select the supplier reference for this operation.

Preferred: This field determines whether this is the preferred supplier for this operation. The preferred supplier is used by default when a works order is created.

Lead Time: The lead time the supplier requires for this operation.

Reference: This field is used on the purchase order and can be used to outline the work required.

Details: This field is used on the purchase order and can be used to provide additional details on the work required.

Quantity Breaks Grid: You can specify up to 5 quantity breaks per supplier, with quantities from and to, the rate for that quantity break, if the rate is on a per item basis or not, and finally the time off site for the quantity break being specified.

Saturday: This field identifies if the supplier works Saturdays.

Sunday: This field identifies if the supplier works Sundays.