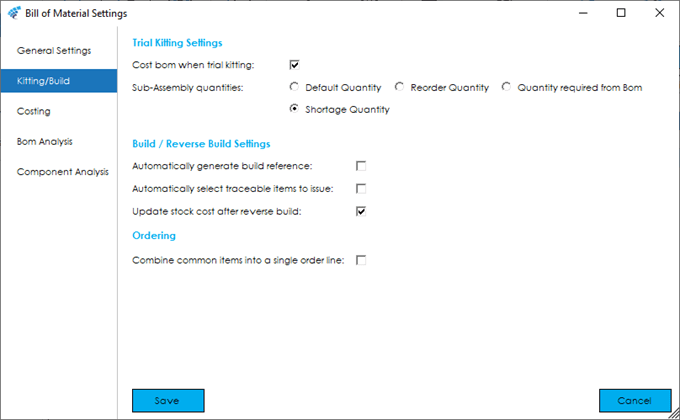

Kitting/Build Settings

Within this section of the BOM Settings, you can determine the settings used when performing Trial Kits on BOMs, along with process settings when Building BOMs and Trial Kitting.

The screen is broken down into the following sections, and the fields within them are described below:

Trial Kitting Settings

Cost BOM when Trial Kitting: This setting determines whether a BOM is re-costed when a trial kit is carried out.

Sub-Assembly quantities: This setting determines what quantity should be used whilst calculating requirements on sub-assemblies when trial kitting a BOM. You can choose between:

Default Quantity: The default quantity specified on the sub-assembly BOM.

Reorder Quantity: The re-order quantity specified on the sub-assembly stock record.

Quantity required from BOM: The quantity specified on the parent BOM.

Shortage Quantity: The quantity of the sub-assembly that the system calculates is short by, in order to process the trial kit.

BOM/Reverse Build Settings

Automatically generate build reference: Determines whether the system will generate a build reference for you or not when carrying out a BOM build. If this is left unchecked, you will need to manually input a unique build reference.

The format for system generated build references is as follows:

“Build <Username> <Date>”

e.g. “Build MARTINM 27/07/2020”

Automatically select traceable items to issue: This setting determines whether the system will automatically select batches or serial numbers for component items that will be issued to a BOM build. If enabled, the system will select batches or serial numbers on a FIFO basis.

Update stock cost after reverse build: This setting determines whether the ‘Last Cost Price’ is updated on the stock record once a BOM reverse build has taken place.

Ordering Settings

Combine common items into a single order line: This setting determines whether the system will combine common purchase items that are determined as shortages, into a single order line on a purchase order, or individual lines.

See also

Related

Other tasks