Operation Times/Costs

To capture actual labour time and/or cost, there are two options within Cim50. You can either use the ‘Enter Operation Times/Costs’ screen or the ‘Timesheets’ option.

The option used will depend on whether you want to enter costs on a works order by works order basis, or on an employee basis. Operation Times/Costs allows you to book time/cost to a specific works order. Timesheets allows you to book time/costs to multiple works orders for a single employee.

Operation Times/Costs

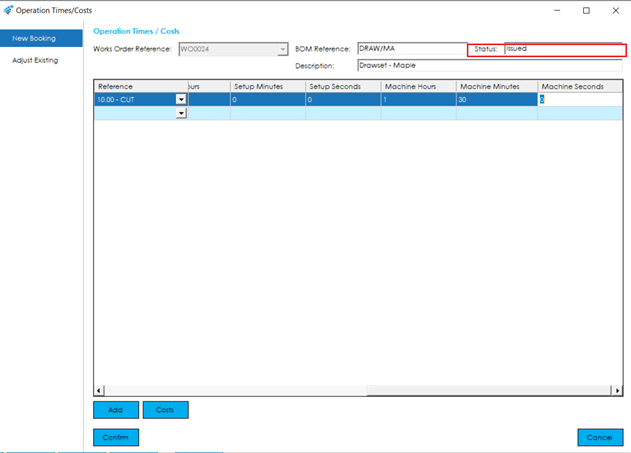

To book time to a works order, highlight the works order you wish to book time/costs again in the main works order list and select the ‘Enter Operation Times/Costs’ option from the Routing menu.

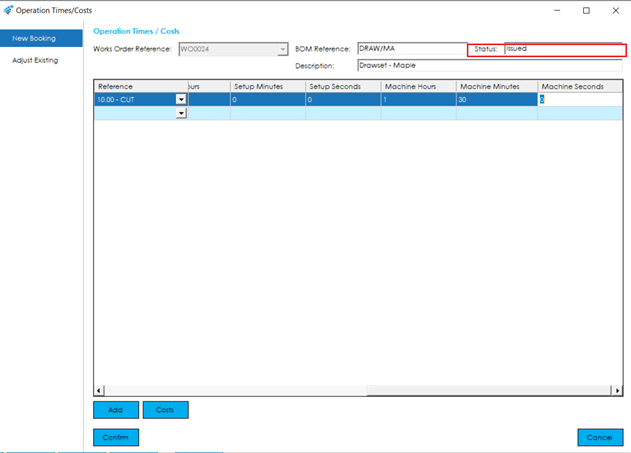

The screen details the works order information at the top and contains a grid where you can specify the times you wish to book to the works order. The status of the works order does not have to be Issued to book labour. You can book labour at any time, up to completion.

To enter a new booking, select the New Booking tab on the left.

You have two options when adding an entry to the grid, you can either click into the first empty row on the grid, selecting the relevant operation from the ‘Reference’ column, and filling in the time, or you can use the Add button.

Adding via the Grid: To add a booking via the grid, navigate to the next blank line in the grid and start by either typing in, or selecting via the dropdown, the relevant operation that you wish to book time/costs against. Press tab, once you have selected, to pre-populate the row details.

You can change the date the booking was done via the date column, which will default to today. You should then confirm how many were completed on this booking, followed by confirming the Hours/Minutes/Seconds that need to be booked, for both labour and machine resources, along with setup time.

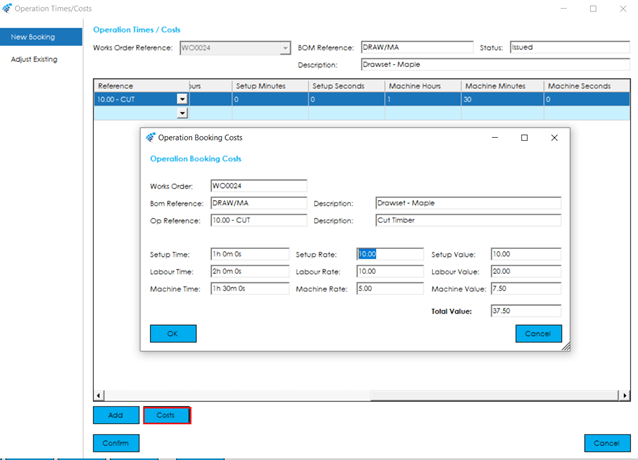

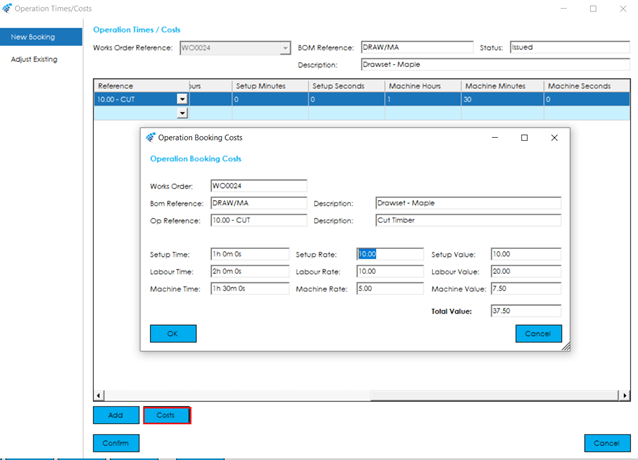

By default, costs will be booked based on the operation configuration on the works order, however, you can view/amend the booking costs by highlighting the relevant line and pressing the Costs button. This will load a screen where you can amend the Setup/Labour/Machine rate accordingly.

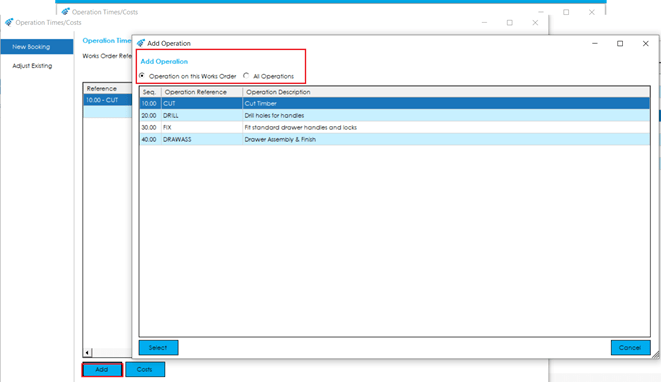

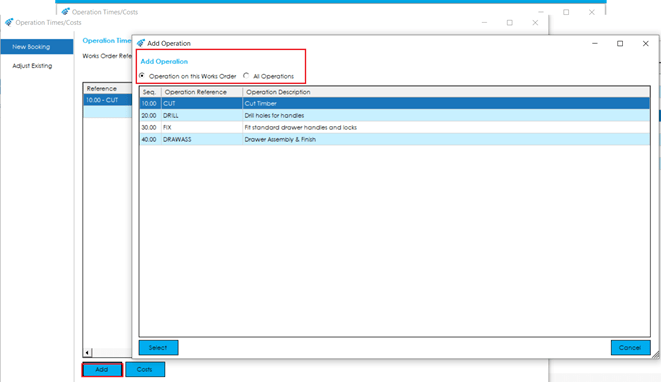

Adding via ‘Add’ Button: Using the Add button will populate a screen where you can select the relevant operation that you wish to book time from. You can either choose an existing operation from the works order or choose one from the ‘All Operations’ list. If you choose to add an operation from the ‘All Operations’ list, the operation will automatically be added to the works order when the booking is confirmed.

Once you have confirmed the operation you wish to add, press the Select button. This will then add the operation to the bottom of the booking grid, where you can then fill in the details on that booking, as per the ‘Adding via the Grid’ details above.

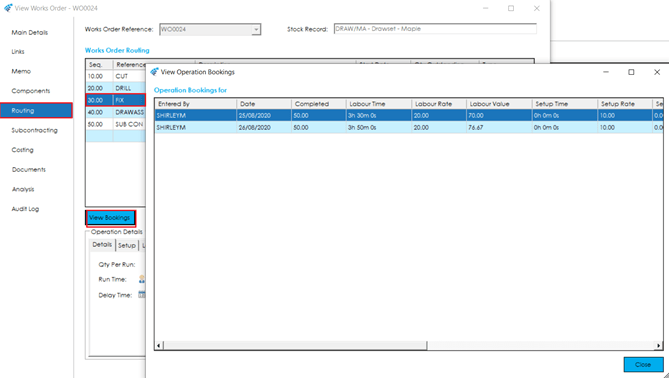

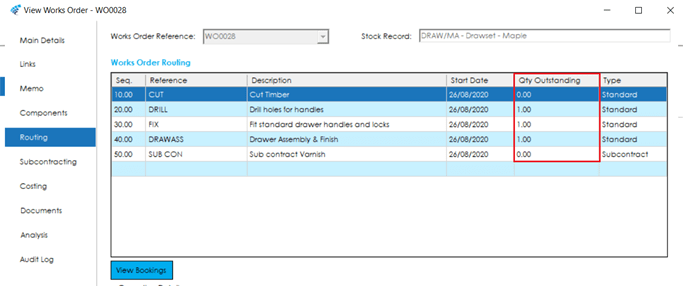

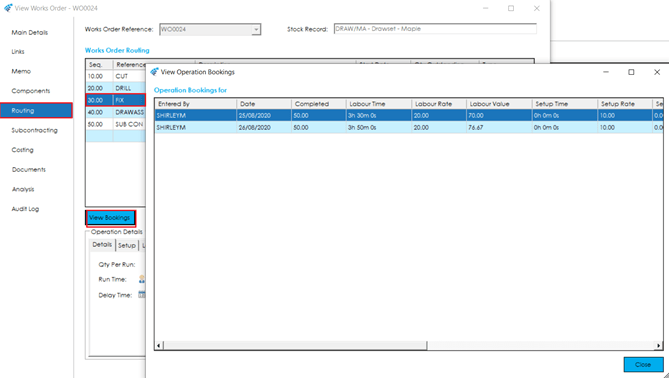

You can view bookings made to a works order via the ‘View’ icon and selecting the Routing tab. Highlight the operation and click on the View Booking button. All information pertaining to bookings made, are displayed.

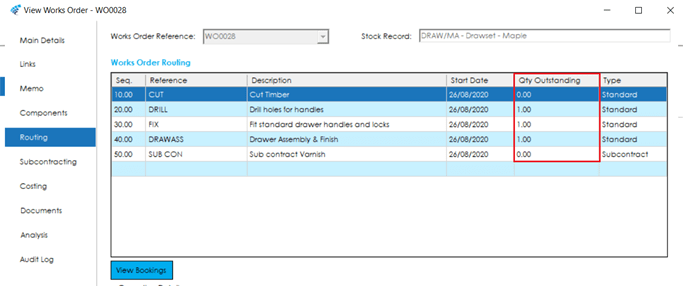

As you book completed quantities to a works order against an operation, the quantity outstanding will decrease. You can view the ‘Qty Outstanding’ by selecting the ‘View’ icon and Routing tab.

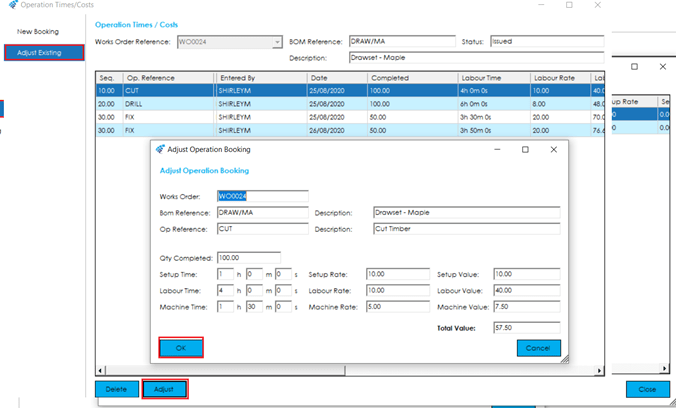

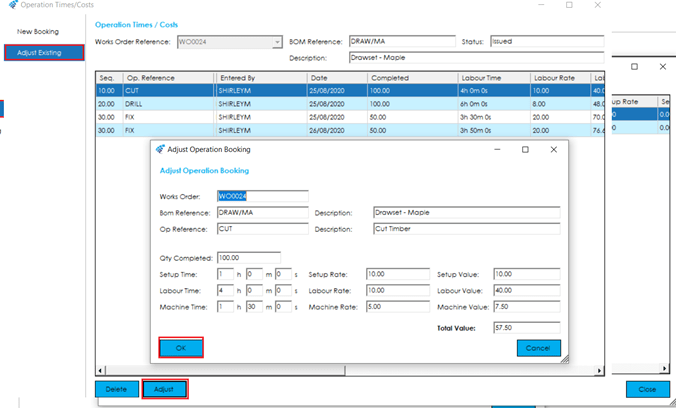

Adjust Existing Booking

If you need to delete or correct an existing booking, select the Adjust Existing tab on the left. A grid will load showing all existing bookings against the works order.

Should you wish to delete a booking, highlight the one you wish to remove and select the Delete button.

If you want to amend a booking, highlight the one you wish to amend and select the Adjust button. A screen will open, where you can change the Setup/Labour/Machine times, along with costs and quantity completed.

To confirm the adjustment, select OK.

Carbon Emissions

Whenever machine time is booked to a works order, the carbon cost for the time booked is added to the works orders total carbon cost.

The calculations used depends on the carbon emission capture mode being used.

Standard Production Calculations:

Whenever machine time is booked to a works order, either as an actual op times booking, via timesheets, or as an expected booking, on completion the system will calculate the carbon cost (KgCO2e) for that booking and add it to the total on the Works Order.

The calculation made depends on the capture mode being used :

Simple: If you are using simple mode to capture carbon costs, the system will use the following formula to calculate the carbon cost for that booking.

[Total Hourly Carbon Cost] * [Machine Hours Booked]

This is then recorded against the works order and can be viewed either via the Works Order Operation Bookings screen, or from the Actual Cost Breakdown Screen.

Complete: If you are using complete mode to capture carbon costs, the system will use the following formulas to calculate the carbon cost for that booking.

([Machine Fuel Hourly Usage Amount] * [Fuel Conversion Ratio])* [Machine Hours Booked]

This is then recorded against the works order and can be viewed either via the Works Order Operation Bookings screen, or from the Actual Cost Breakdown Screen.