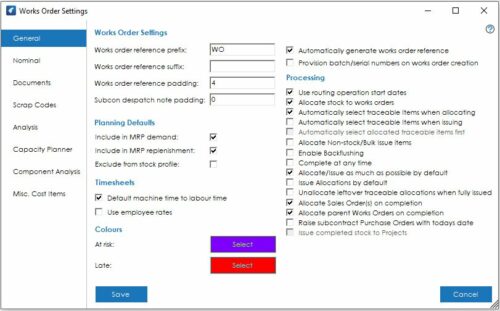

The screen is broken down into the following sections, and the fields within them are described below.

General Settings

The General settings tab allows you to configure ‘Defaults’ for various aspects on new works order records, along with colour codes and various processing settings as follows.

Works Order Settings

Works Order Reference Prefix: You can specify a prefix to be used in works order references for newly generated works orders, up to 5 characters long.

Works Order Reference Suffix: You can specify a suffix to be used in works order references for newly generated works orders, up to 5 characters long.

Works Order Reference Padding: This setting determines the padding length to be used when generating new works order numbers.

Subcon Despatch Note Padding: This determines the padding length to be used when generating new subcontract despatch note numbers.

Automatically Generate Works Order Reference: This setting determines whether the system will generate new works order numbers for you, or whether they will be manually entered.

Note: If you manually create the works order number, the Prefix, Suffix, and Padding will be part of the manual entry, and not generated.

Provision batch/serial number on works order creation: This determines the default setting used when creating a new Bill of Material.

Planning Defaults

Include in MRP Demand: The default setting to determine whether a works order should be included in the MRP Demand list or not.

Include in MRP Replenishment: The default setting to determine whether a works order should be included in the MRP Replenishment list or not.

Exclude from Stock Projection: The default setting to determine whether a works order should be excluded from the Stock Projection screen.

Colours

You can define the colour to be used for ‘At Risk’ and ‘Late’ orders within the works order list.

To amend a colour, click the button for the relevant status, and choose your desired colour from the colour palette.

Note: At Risk is determined by the Production Safety Lead Time, as per the MRP tab of the Stock Record.

Processing

Use Routing Operation Start Dates: This setting determines whether a works order contains individual operation start dates, or whether they all inherit the works order start date.

Allocate Stock to Works Orders: This setting determines whether you wish to allocate stock to works orders or not.

Automatically select Traceable Items when Allocating: This setting determines whether traceable batches/serial numbers are automatically selected on a FIFO basis when allocating, or whether you must manually select the appropriate batches/serial numbers.

Note: This option should not be selected if ‘Allocate Stock to Works Orders’ is not selected.

Automatically select Traceable Items when Issuing: This setting determines whether traceable batches/serial numbers are automatically selected on a FIFO basis when issuing, or whether you must manually select the appropriate batches/serial numbers

Automatically select Allocated Traceable Items First: This option is only available if the above 2 settings are selected. If you are flexible with Allocation and Issue, and change between the two, then the system will use the ‘Allocated Traceable Items’ when issuing.

Allocate Non-stock/Bulk Issue Items: This setting determines whether items marked as Non-Stock or Bulk Issue will be shown as allocated to the works order or not. With this setting enabled the works order allocated quantity would be set to the quantity required at the point you first go to allocate stock to a job. This allocation is just on the works order, with nothing showing as allocated in stock/products.

Enable Backflushing: This setting determines whether the option to backflush component stock is available when completing works orders.

Note: This feature is only carried out on Completion of the Job if no allocation or issue has been carried out. Component stock is only downdated at this point.

Complete at any time: This setting determines whether you can complete a works order regardless of component issue status.

Note: This means that a job can be completed before all the required components have been issued, and may cause jobs to be under costed, and/or incorrect component stock quantity balances.

Allocate/Issue as much as possible by default: This setting will allocate/issue up to the required quantity automatically if sufficient stock is available. If there is insufficient stock, Cim50 will allocate/issue all it can up to the required qty.

Issue Allocations by default: This setting, combined with the above Allocate/Issue as much as possible by default setting will issue the quantity allocated by default when issuing stock to a works order.

Unallocate leftover traceable allocations when fully issued: Enabling this setting will result in any batches/serial numbers that were allocated on a FIFO basis but not subsequently issued to the works order being unallocated automatically when fully issued.

Allocate Sales Order(s) on Completion: When a Works Order is completed, an allocation to the Sales Order will automatically take place.

Allocate parent Works Orders on Completion: When a lower level works order is completed, an option to allocate the completed assemblies directly to the parent works orders, will be available.

Raise Subcontract Purchase Orders with today’s date: This setting determines whether any subcontract orders raised have the order date set as the date the order was raised, or the date it should be ordered based on the operation start date less the subcontract supplier lead time.

Issue completed stock to Projects: This setting determines whether items completed via works orders should be automatically issued to a project linked to the works order being completed.

Note: Users can override this setting at the point of completion if desired.